Dragonplate UAV Quadcopter Frame Kits

DragonPlate offers carbon fiber UAV quadcopter kits that utilize our advanced products and a unique, cost effective, design. The kits come as a DIY version that includes the raw materials to be cut down and customized or as a Ready to Assemble version with pre-cut and pre-drilled holes*. The standard UAV has a main body plate and four arms to mount your choice of motors, controllers, and batteries. Our deluxe model includes a convenient set of landing arms for faster landings on diverse terrain and an upper body for mounting of custom hardware.

DragonPlate offers carbon fiber UAV quadcopter kits that utilize our advanced products and a unique, cost effective, design. The kits come as a DIY version that includes the raw materials to be cut down and customized or as a Ready to Assemble version with pre-cut and pre-drilled holes*. The standard UAV has a main body plate and four arms to mount your choice of motors, controllers, and batteries. Our deluxe model includes a convenient set of landing arms for faster landings on diverse terrain and an upper body for mounting of custom hardware.

Choose Your Kit

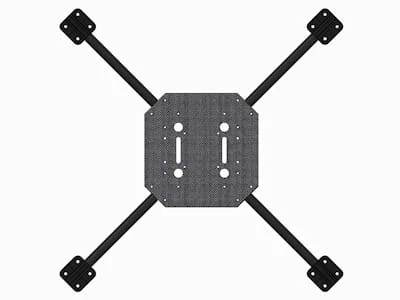

STANDARD

Standard Ready-to-Assemble Kit

Download CAD Model

This PDF must be opened in Adobe PDF Reader to view the CAD Model

View CAD Model (PDF)

DELUXE

Download CAD Model

This PDF must be opened in Adobe PDF Reader to view the CAD Model

View CAD Model (PDF)

Contents of Quadcopter Frame Kits

(electronics, motors and rotor blades not included)

DIY STANDARD KIT

- (1) 1/8" CF matte finish birch core, 6" x 6"

- (1) 0.5" CF pultruded tube, 48" long

- (8) 0.5" horizontal tube flange

- All necessary hardware

DIY DELUXE KIT

- (1) 1/8" CF matte finish birch core, 12" x 12"

- (1) CF angle, 1/32" x 1" x 12" long

- (1) 0.5" CF pultruded tube, 48" long

- 0.25" CF pultruded tube, 48" long

- (8) 0.5" horizontal tube flange

- All necessary hardware

READY-TO-ASSEMBLE STANDARD KIT

- (1) 1/8" CF matte finish birch core mounting plate (cut & drilled)

- (4) 0.5" CF pultruded motor arm

- (8) 0.5" horizontal tube flange

- All necessary hardware

READY-TO-ASSEMBLE DELUXE KIT

- (1) 1/8" CF matte finish birch core mounting plate (cut & drilled)

- (1) 1/8" CF matte finish birch core top plate (cut & drilled)

- (4) 0.25 CF pultruded plate stand-off

- (2) 1/8" CF matte finish birch core landing gear arm (cut & drilled)

- (2) CF angle bracket for landing gear

- (4) 0.5" CF pultruded motor arm

- (8) 0.5" horizontal tube flange

- (2) 0.25" CF pultruded landing gear foot

- All necessary hardware

* Motor mounts not pre-drilled to accomodate variations in motor mounting requirements