Carbon Fiber Deflection Optimized Telescoping Tubes

![]()

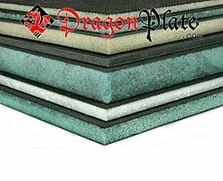

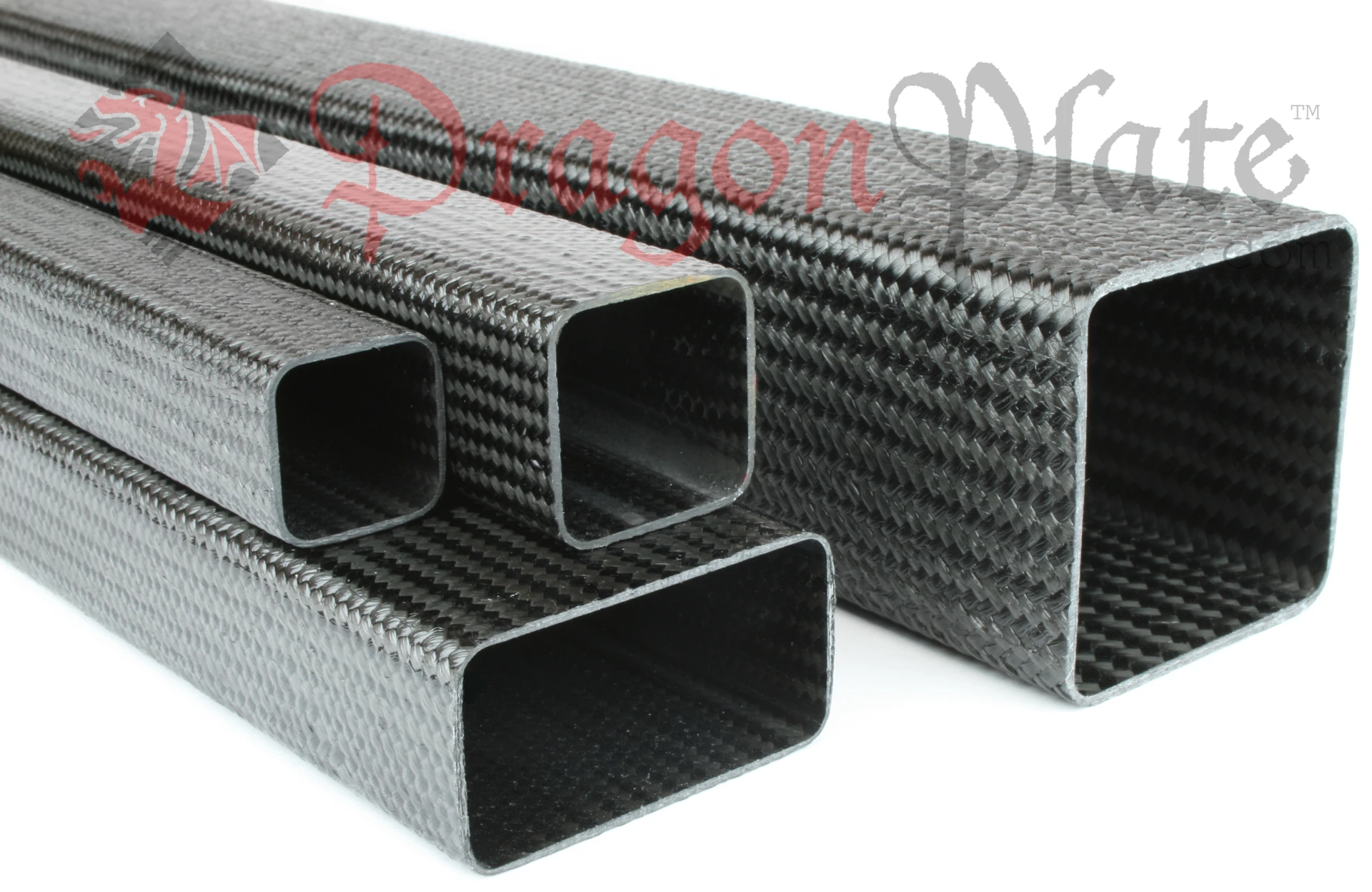

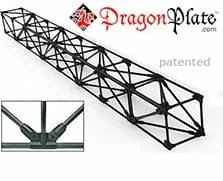

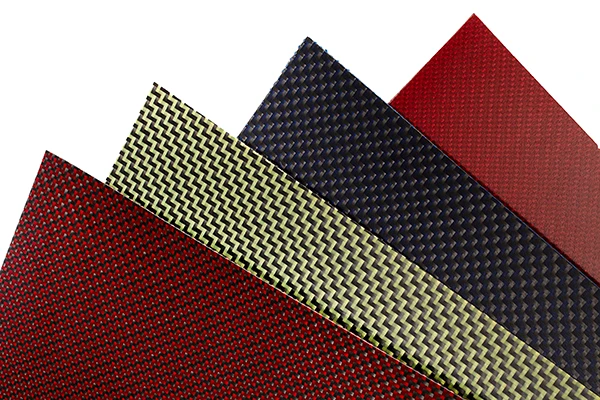

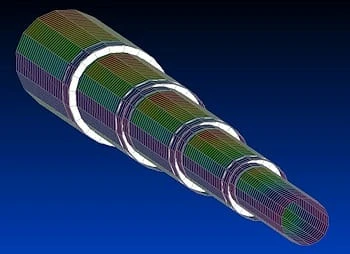

Dragonplate deflection optimized telescoping tubes are engineered using Nastran FEA composite modeling. Unlike the standard and rugged lines, optimized telescoping tube systems make use of a proprietary blend of materials, providing an ideal balance between weight, strength, and stiffness. Dragonplate works with customers to analyze a specific application and develop an optimized solution. Typical design variables include extended and retracted length, max and min tube diameters, temperature requirements, finish, impact toughness, and many others. Through trade-off studies, the Dragonplate engineering team helps customers develop truly optimized systems.

Dragonplate deflection optimized telescoping tubes are engineered using Nastran FEA composite modeling. Unlike the standard and rugged lines, optimized telescoping tube systems make use of a proprietary blend of materials, providing an ideal balance between weight, strength, and stiffness. Dragonplate works with customers to analyze a specific application and develop an optimized solution. Typical design variables include extended and retracted length, max and min tube diameters, temperature requirements, finish, impact toughness, and many others. Through trade-off studies, the Dragonplate engineering team helps customers develop truly optimized systems.

Contact Us to Develop Optimized Telescoping Tubes

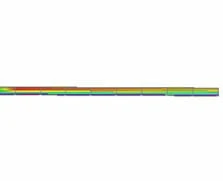

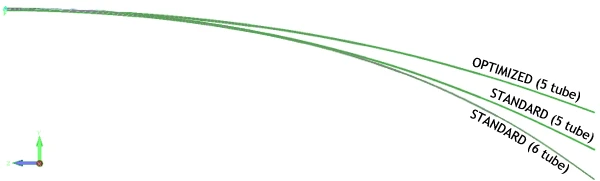

An FEA case of a cantilevered beam with 0.5 pounds acting on the end was applied to three different tube assemblies. The standard assembly is a 6 tube construction built totaling to 432" when fully extended. The slightly improved version is a 5 tube construction built using 8’ lengths out to the same extension. As the FEA indicates, due to an increase in overlap, the deflection improves by almost 18%. Finally, we optimized the system by using a 5 tube assembly with our proprietary layup. The result is almost a 30% reduction in the deflection compared to the standard construction.