Gauging the Thickness of Carbon Fiber Sheets

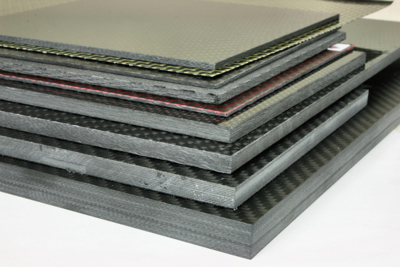

Carbon fiber sheets come in a wide range of thicknesses to accommodate a variety of projects. The thinner the sheet, the more easily it can bend without fatiguing. This is useful to know if you need to cover an item with an overlay. On the other hand, a thicker carbon fiber sheet is virtually impossible to bend, which is useful if you need a strong, rigid material to build your design.

Carbon fiber sheets come in a wide range of thicknesses to accommodate a variety of projects. The thinner the sheet, the more easily it can bend without fatiguing. This is useful to know if you need to cover an item with an overlay. On the other hand, a thicker carbon fiber sheet is virtually impossible to bend, which is useful if you need a strong, rigid material to build your design.

Common Carbon Fiber Sheet Thicknesses

Carbon fiber sheets come in a variety of thicknesses. These vary slightly by manufacturer, but most offer thicknesses similar to the following. Most carbon fiber sheet manufacturers offer custom options as well. Common thicknesses include:

- 0.013” (0.33 mm)—This is an extremely thin carbon fiber sheet, approximately the thickness of two stacked pieces of computer paper. You can easily cut this carbon fiber sheet with a pair of household scissors, and it bends around a one-inch cylinder quite easily. Carbon fiber sheets of this thickness are often used for cosmetic purposes.

- 0.020” (0.50 mm)—About the thickness of five stacked sheets of paper they can be cut with a pair of heavy-duty scissors. They can still bend, but not as easily or as tightly as the .013” carbon fiber sheets. A sheet of this thickness bends around a cylinder of about four inches. It is a useful thickness when your main purpose is still cosmetic, but you need more strength than a thinner sheet can offer. The added thickness and stiffness offers some camouflage when covering a substrate with slight imperfections.

- 0.032” (0.80 mm)—These are fairly rigid carbon fiber sheets, yet they are still somewhat flexible. They are nearly as thick as an audio CD. Carbon fiber sheets of this thickness are typically used flat, but they can bend around a 10-12 inch diameter cylinder. These function as a semi-rigid veneer or a light structural material. You can cut this thickness with tin snips, a saw, multiple scores with a razor knife, or an abrasive cutting wheel such as a Dremel tool. You’ll want to use 220-grit sandpaper to clean the edges after cutting if you need a smooth edge.

- 0.062” (1.57 mm)—Slightly thicker than the audio CD example used above, this is a fairly rigid carbon fiber sheet. If you need impact resistance or are working on a small structural project, this is a great option. With only slight flexibility, the smallest cylinder you could bend it around is about 24”. It should only be cut with a carbide router, CNC bit, or abrasive cutoff wheel.

- 0.125” (3.175 mm)—This ⅛” thick carbon fiber sheet is extremely durable and rigid. It’s the perfect material for structural applications. Use a saw, carbide, bimetal, or diamond-coated cutting tools to cut carbon fiber sheets of this thickness. Smooth the edges with sandpaper.

- 0.25” (6.35 mm)—At a full 1⁄4” thick, these carbon fiber sheets are overkill for most projects. Small carbon fiber parts can be cut from these sheets. To cut a carbon fiber sheet this thick, you definitely need professional tools with carbide, bimetal, or diamond-coated cutting surfaces.

Safety First When Cutting Carbon Fiber Sheets

A lot has been written about the dangers of cutting carbon fiber sheets. As with most tasks, a little forethought ahead of time can prevent accidents in the end. First, be sure you are using an appropriate cutting tool for the job. The correct tool can prevent damage to both the carbon fiber sheet and the person cutting it. Appropriate cutting tools for each thickness of the carbon fiber sheet above are listed in the description. Fast cutting using a jigsaw or circular saw is not recommended since this creates a lot of carbon fiber dust, which irritates the eyes and lungs.

Fast cutting techniques also tend to leave an extremely rough edge when cutting carbon fiber sheets. When cutting thicker sheets, waterjet or CNC routers can be used. When cutting carbon fiber sheets, it’s always a good idea to protect the surface from scratches with masking tape or something similar.

As for protecting the person cutting the carbon fiber sheet, it’s always a good idea to wear the proper personal protective equipment (PPE). This includes eye protection, long sleeves, a mask, and gloves. The main dangers of cutting carbon fiber sheets are splinters and dust. Protecting yourself from these hazards goes a long way in preventing accidents.

Carbon fiber sheets have many uses and come in a wide array of thicknesses to accommodate those uses. Whether you need a thin veneer to cover a surface for a beautiful finish, or a thick sheet of material to ensure the strength of your project, carbon fiber is often the best option. Working directly with a quality carbon fiber manufacturer ensures you’ll find the right sheet thickness for your project.