How to Connect Carbon Fiber Tubes

There are several ways to connect carbon fiber tubes, but some are structurally more preferable. Some carbon fiber tube manufacturers connect tubes by drilling into them and pinning or bolting them, but that is not a recommended method as it compromises the tube wall and weakens the tube. It is better to use DragonPlate carbon fiber tube connectors that that are are specifically designed for that purpose. There are several available, including:

- Modular connectors, including blocks, cubes, links, and clevis connectors

- Molded pultruded carbon fiber tube connectors

- Threaded end and quick-release connectors

- Carbon fiber plate gussets

By combining carbon fiber tubes and these connectors, you can easily create complex two-dimensional or three-dimensional structures that are easy to assemble and disassemble and allow for adjustable angle joints.

Connecting Roll Wrapped Carbon Fiber Tubes Using Modular Connectors

Roll-wrapped tubes are best connected using modular connectors. Modular connectors are made from anodized aluminum. Using a patented ridged and slotted design, these connectors are designed to strengthen the bond against the possibility of metal-to-carbon delamination caused by the differential thermal expansion of carbon fiber and aluminum.

It is quite simple to assemble modular carbon fiber tube connectors:

- Lightly sand the inside of the tube.

- Clean the surfaces that will be bonded.

- Mix the epoxy.

- Apply the epoxy.

- Insert the connector.

- Wipe away any excess adhesive.

By combining various modular connectors and roll wrapped carbon fiber tubes, a wide range of lightweight and stiff carbon fiber tube structures can be built.

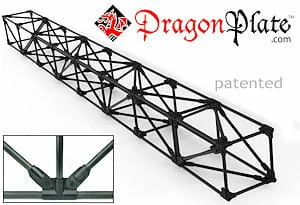

Connecting Pultruded Carbon Fiber Tubes Using Molded pultruded carbon fiber tube connectors and Quick-Release Connectors

For less demanding applications, molded pultruded carbon fiber tube connectors can be used to create complex structures with pultruded carbon fiber tubes. Threaded end connectors with a quick release can be used to allow easy assembly and disassembly of tubes and tube structures. Long truss structures comprised of shorter segments of up to eight feet in length can thus be built. Due to the low weight and high strength of carbon fiber tubes, this application is particularly useful for camera boom arms, lighting fixtures, or tools that can be broken down for easier transportation.

To assemble CF tube structures structures using the Molded carbon fiber pultruded tube connectors

- Mockup the joint.

- Sand the bonding area.

- Clean the surfaces to be bonded.

- Apply the epoxy to the tube and connector

- Assemble the structure by using the supplied plastic screws to assemble the molded gussets around the tube or slide the multi-angle connector on to the end of the tube.

- Clean any excess epoxy.

To install quick-release carbon fiber tube connectors:

- Follow the instructions above for modular connectors to bond the two quick-release connector adapters into the ends of the pultruded carbon fiber tubes.

- Thread the quick-release male and female ends into these aluminum adapters.

A locking version of the quick-release connector is available for single-use applications, prohibiting rotation when the lock is engaged. Alternatively, a version is also available that contains a groove that allows the component to rotate. This simple groove in the quick-release connector eliminates the need for complex fixturing when assembling sections of the truss.

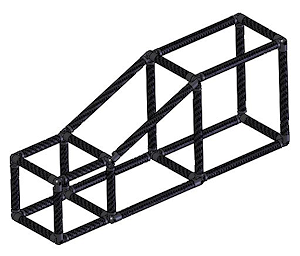

Connecting Square and Rectangular Carbon Fiber Tubes Using Plate Gussets

Plate gussets are used to reinforce carbon fiber tube structures built with square or rectangular tubes. The carbon fiber laminate thickness of the plate gusset kit equals the thickness of the tube wall. To assemble carbon fiber plate gussets with carbon fiber tubes:

- Mockup the joint.

- Drill small rivet holes to match the plate gusset into the carbon fiber tube.

- Sand the bonding area.

- Clean the surfaces to be bonded.

- Apply the epoxy.

- Use the supplied rivets to attach the gusset to the tube.

- Clean any excess epoxy.

Note: Refer to the detailed instructions provided with the plate gusset kit for actual assembly.

An infinite combination of lightweight and robust structures can be built using plate gussets to connect square and rectangular carbon fiber tubes.

By combining various shapes and styles of carbon fiber tubes and carbon fiber tube connectors, you can create just about any structure you can imagine. As with all carbon fiber products, these structures are durable, strong, and lightweight. When combined with the proper connectors, they can be built for quick and easy assembly and disassembly, allowing ease of portability to be added to the list of features. By selecting connectors that do not require drilling into the carbon fiber tubes, you also ensure that the structural integrity and strength of the carbon fiber tubes remain intact. Now it’s time to get designing. All that stands in your way is your imagination!