How to Identify Quality Carbon Fiber Sheets

Carbon fiber sheeting is a high-performance product, and can be relatively expensive to purchase. Unfortunately, there are companies selling less expensive carbon fiber products which are of lower quality. Purchasing carbon fiber sheeting is definitely a time when "you get what you pay for." If a project justifies the expense of using carbon fiber sheet over another material, it is wise to do your research and invest in a quality product, rather than looking only for the lowest price. Here are a few characteristics to look for, to ensure you’re making a quality purchase.

Carbon fiber sheeting is a high-performance product, and can be relatively expensive to purchase. Unfortunately, there are companies selling less expensive carbon fiber products which are of lower quality. Purchasing carbon fiber sheeting is definitely a time when "you get what you pay for." If a project justifies the expense of using carbon fiber sheet over another material, it is wise to do your research and invest in a quality product, rather than looking only for the lowest price. Here are a few characteristics to look for, to ensure you’re making a quality purchase.

Flatness

Quality carbon fiber sheet should lie perfectly flat. When you place the carbon fiber sheet on a flat surface and get eye-level with it, there should not be any sort of waves or warps in the sheet. Neither should there be any bends or creases marring the surface of the sheet.

Gloss Carbon Fiber Sheets and Veneers

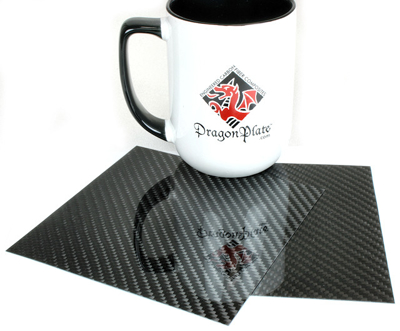

A gloss carbon fiber sheet finish should look like glass. You do not want to see any bumps, ridges, or indentations in the finish. The carbon fibers should be visible uncrushed beneath a surface that appears smooth and crystal clear. The tows should not appear to be flattened. The tows (threads) of a 3k veneer weave each consist of 3,000 individual fibers. The fine appearance of these individual fibers is what gives carbon fiber its unique appearance. The perfectly clear gloss coat shows off the texture of this beautiful and unique material.

Matte Carbon Fiber Sheets

Matte Carbon fiber sheets should have a smooth finish that is less reflective gloss sheets. The carbon fiber should still be visible beneath the surface but the epoxy should not have the “mirror like” finish of the gloss sheet. Matte carbon fiber sheets have a more durable surface that is harder to scratch.

Textured Carbon Fiber Sheets

Textured Carbon fiber sheets are intended for bonding and adhesive assembly and do not have a cosmetic finish. The finish should resemble the fine fabric texture of the peel-ply fabric that was applied in the fabrication process and later pulled off to create a textured surface that would adhere well to an adhesive.

Fiber Straightness

Defects in fiber orientation on surface sheets affects the cosmetic appearance and mechanical properties and provides a possible indication of a problem with ply orientation in buried layers as well as underlying sheets as well. The fibers should be at the correct angular orientation, and straight.

Dimensions

Cutting tolerances of carbon fiber sheeting are typically ±.125”. Therefore, a high-quality carbon fiber sheet measures within ⅛" of the dimensions stated in the product description.

When determining what material best suits the needs of a project, carbon fiber sheeting offers many benefits. It is lightweight, strong, and offers incredible mechanical properties. Additionally, it is also a relatively expensive material to work with. Doing a little research beforehand to ensure you are working with a manufacturer who fabricates only the highest quality carbon fiber sheeting pays off many times over in the long run.

Shop our wide selection of carbon fiber sheets and plates