The Benefits of Investing in Commercially Made Carbon Fiber Panels Versus Making Your Own

A lot has been written about DIY carbon fiber fabrication. While it is certainly possible to create smaller carbon fiber projects on your own, the larger the project, the more difficult DIY becomes. When it comes to working with carbon fiber panels, there are many benefits to investing in a product from a reputable manufacturer over making your own.

A lot has been written about DIY carbon fiber fabrication. While it is certainly possible to create smaller carbon fiber projects on your own, the larger the project, the more difficult DIY becomes. When it comes to working with carbon fiber panels, there are many benefits to investing in a product from a reputable manufacturer over making your own.

What is a Carbon Fiber Panel?

The first thing to understand is the difference between carbon fiber sheets, plates, and panels. They are all flat sheets of carbon fiber composite, but there are important differences.

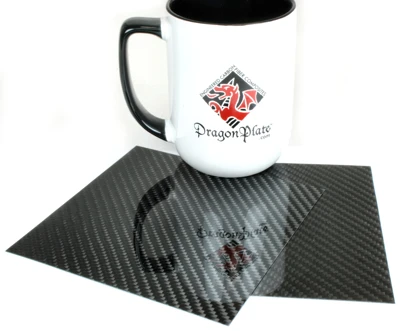

Carbon fiber sheets are typically veneers that are used more for aesthetics than for structural integrity. A beautiful carbon fiber sheet will clearly show the fibers and texture of the carbon. They can be found in thicknesses of 1/32”. The thinner pieces are made from orthotropic laminates; meaning they will have different strengths depending on the axis the stress is applied.

Carbon fiber plates are thicker and more solid than veneer sheets and offer more strength and stiffness-to-weight ratio benefits. They can also be orthotropic but the thicker pieces can add additional layers allowing for quasi-isotropic properties. This adds rigidity along multiple axes and complexity in proper manufacturing.

Carbon fiber panels are sandwich sheets with cores made up of various materials based on the consumer’s needs. Cores are made from foam, balsa, or honeycomb to increase thickness and bending stiffness, disperse impact, and keep the materials lightweight. Often these sheets are made with ‘prepreg’ fabrics. These fabrics are pre-impregnated with resin (typically epoxy) and all the curing agents. This process allows for greater control and consistency in the products.

How Are Carbon Fiber Panels Made?

Carbon fiber panels start with the core material. The core is then bonded on both sides with a carbon fiber layup to create a laminate. Each laminated sheet has a symmetrical and balanced carbon fiber layup schedule with core materials that vary based on thickness. A carbon fiber panel, therefore, combines the superior strength and stiffness properties of carbon fiber with a lower density core material. The carbon fiber layup can be anything from a basic plain weave to quasi-isotropic laminate sheets.

Why Investing in Carbon Fiber Panels is Preferable to Making Your Own

There are many steps in creating carbon fiber panels and the process includes considerable investment and skills, including the carbon fiber, epoxy resins, core materials, molding materials, and vacuum equipment. It is also difficult to obtain commercial-grade supplies. Then one has to take into account all the quality control checks that are done by professional manufacturers to ensure integrity and consistency throughout the whole piece. If one point is weaker than the rest, the whole component is more likely to prematurely fail; completely defeating the point of using the carbon fiber.

An experienced carbon fiber panel manufacturer can ensure your carbon fiber sheets, plates, or panels do exactly what you intend them to do, every time. View the complete line of DragonPlate sheets to find the one that's right for your application.