Using DragonPlate Carbon Fiber Composites to Build UAVs and Drones

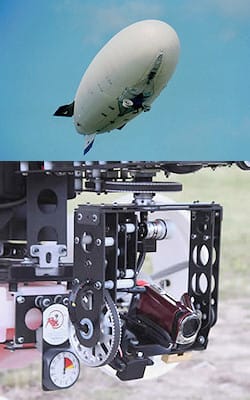

Dragonplate offers a wide range of off-the-shelf components ideal for both fixed and rotary wing UAVs. With the rapid development of all different types of drones, mission capabilities are paramount, and having lightweight, strong composite materials for the frame, body, mounting plates, etc, can mean the difference when trying to meet your airframe weights goals.

Dragonplate offers a wide range of off-the-shelf components ideal for both fixed and rotary wing UAVs. With the rapid development of all different types of drones, mission capabilities are paramount, and having lightweight, strong composite materials for the frame, body, mounting plates, etc, can mean the difference when trying to meet your airframe weights goals.

From the hobbyist to the professional, Dragonplate has the building materials you will need to create virtually any drone. Our off-the-shelf line of carbon fiber flat sheets, braided and roll-wrapped tubes, angles, and a wide array of pultruded materials provide all of the basics. Our patented connector system for pultruded tubes, as well as our modular connectors for braided and roll-wrapped tubes provide an ideal method for making frames, especially for multi-rotor helicopters. For assembly, an array of structural epoxies and fasteners are also available.

From the hobbyist to the professional, Dragonplate has the building materials you will need to create virtually any drone. Our off-the-shelf line of carbon fiber flat sheets, braided and roll-wrapped tubes, angles, and a wide array of pultruded materials provide all of the basics. Our patented connector system for pultruded tubes, as well as our modular connectors for braided and roll-wrapped tubes provide an ideal method for making frames, especially for multi-rotor helicopters. For assembly, an array of structural epoxies and fasteners are also available.

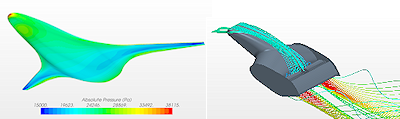

In addition to the Dragonplate line of carbon fiber products, we also offer our industry, government, and military partners engineering services and full prototyping and production capabilities. Our in-house engineering provides both CFD and FEA analysis services for determining the aerodynamics, stability, and structural loads and stresses. The Dragonplate design and prototyping group utilizes Solidworks CAD modeling and Mastercam for CNC tool path generation. And our ISO 9001 certified production team is ready and able to help scale up your program to large volumes.

In addition to the Dragonplate line of carbon fiber products, we also offer our industry, government, and military partners engineering services and full prototyping and production capabilities. Our in-house engineering provides both CFD and FEA analysis services for determining the aerodynamics, stability, and structural loads and stresses. The Dragonplate design and prototyping group utilizes Solidworks CAD modeling and Mastercam for CNC tool path generation. And our ISO 9001 certified production team is ready and able to help scale up your program to large volumes.

Whether you are ready for production quantities of custom-molded rotors, airframe components and assembly, or you are still in the design and research phase of the project, let us know how we may help accelerate your project into the skies.

Whether you are ready for production quantities of custom-molded rotors, airframe components and assembly, or you are still in the design and research phase of the project, let us know how we may help accelerate your project into the skies.

In The News

DragonPlate Quadcopter Kits

DragonPlate Quadcopter Kits

DragonPlate offers carbon fiber UAV quadcopter kits that utilize our advanced products and a unique, cost effective, design. The frame kits come as a DIY version or as a Ready-to-Assemble version.

Most Innovative Design

Most Innovative Design

University of Montreal Polytechnique quad-copter wins first place and "Most Innovative Design" at the 2016 American International Aerial Robotics Competition (IARC) using DragonPlate carbon fiber composites.

Featured in Smithsonian's Air & Space Magazine

Featured in Smithsonian's Air & Space Magazine

DragonPlate carbon fiber composites have been featured in the July 2014 issue of Smithsonian's Air & Space Magazine. See how builder Ed Darack created a drone using standard DragonPlate carbon fiber components to construct the body.

DragonPlate Builds Rocket Body For NASA

DragonPlate Builds Rocket Body For NASA

DragonPlate worked with NASA Marshall Space Flight Center to build a carbon fiber rocket. The goal of this program is to take small satellites into space. DragonPlate manufactured the carbon fiber components for the main body and nose cone.