What Does Stress, Strain, and Modulus of Elasticity Mean, and How Does it Relate to Carbon Fiber?

Relationship Between Stress and Strain

The relationship between stress and strain in a material is determined by subjecting a material specimen to a tension or compression test. In this test, an axial force is steadily increased on the specimen, and the deflection is measured. These measurements can be plotted as a load-deflection curve. The deflection depends on the material's elastic modulus and the specimen's geometry. To focus on material behavior without considering geometry, it is helpful to generalize the data and remove the effect of geometry.

Modulus of Elasticity, a.k.a. "Young's Modulus" or "Tensile Modulus"

The modulus of elasticity measures a material's resistance to elastic (non-permanent) deformation under applied stress on a certain axis. This can also be interpreted as the "stiffness" of a material. The factors determining this measurement are the stress applied to the material divided by the strain exhibited. "E" is the symbol for this measurement.

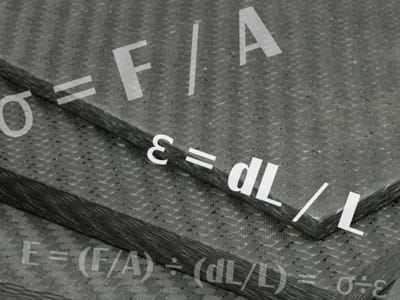

Stress σ = F / A

F stands for applied force, measured in Newtons or pounds (N or lb), and A represents the stressed area of the material (m2 or in2). The resulting measurement, σ, is N/m2 or lb/in2.

Strain

Strain ε = dL / L

dL is the offset (change) of the material's length along the axis measured (m or in). L is the original measurement of the material. The measurement units cancel out, so Strain is a unitless measurement.

Modulus of Elasticity

Modulus of Elasticity E = (F/A) ÷ (dL/L) = σ÷ε

Since Strain is a unitless measurement, the unit used for E is the same as that used for stress. However, N/m2 = Pascal (Pa), and often E is reported in Gigapascals (GPa = Pa x109). Alternatively, lb/in2 = psi, and E is then expressed in Megapounds/square inch (Mpsi or Msi = psi x106) or Kilapounds/square inch (Kpsi or Ksi = psi x103).

Bulk Modulus Elasticity

Bulk Modulus Elasticity is a measure of the resistance of a substance to uniform compression. It is expressed as the ratio of stress applied to the change in volume that results from applying that stress. Bulk Modulus Elasticity measures the degree to which a force can change a material's size or shape and indicates whether this material may be used in applications where it must maintain its size over time.

For example, bulk modulus elasticity is important when designing parts for an aircraft since parts may change shape and size due to frequent flight pressure cycles. In these cases, a material with good bulk modulus elasticity would help ensure that components maintain their intended function throughout their lifespan.

The Diving Board Example of Stress Strain Modulus

Think of a wooden diving board. You’re standing on one end, and it’s supported on the other end. As the board flexes under your weight, the shape changes. If you measure the differences using a variety of weights, the data points will create a slope, which creates your Modulus of Elasticity. The rigidity of the diving board depends on the type of wood used. Douglas Fir has a Modulus of Elasticity of 13 GPa (1.9 Msi). Oak has an E value of 11 GPa (1.6 Msi), and pine is 9 GPa (1.3 Msi), which is more flexible than Douglas Fir. Modern-day diving boards are made of aircraft-grade aluminum 69 GPa (10 Msi).

Stress Strain Modulus Relationship with Carbon Fiber

So, how does that relate to carbon fiber? Carbon fiber technology is an amazing breakthrough in lightweight, rigid materials. Items formerly made with standard building materials can be manufactured lighter and stronger with carbon fibers. A diving board needs to flex; one made of carbon fiber (228 GPa, 33 Msi) would not be practical. However, a drone's propeller or an enclosure for sensitive equipment requires a rigid, lightweight material. When every ounce or gram counts, carbon fiber materials can make the difference between staying grounded and taking off.

Unmanned aerial vehicles (UAVs) and larger aircraft can benefit from carbon fiber's weight-saving properties and sleek look. Bicycle manufacturers can greatly increase their products' strength and durability while decreasing weight. Manufacturers can make stylish, modern, lighter-weight, and longer-lasting equipment and furniture. Lightweight, unmanned vehicles can work where no human can because of either weight restrictions or stress on the body (E value of bone is 76 GPa (11 Msi)). With carbon fibers, you get a Modulus of Elasticity starting around 228 GPa (33 Msi), while some high-rigidity carbon fiber materials have E values of 760 GPa (110 Msi).

Other Applications

What else can be achieved with carbon fiber? Sound engineers can use carbon fibers' strength, durability, and natural resonance to make instruments and sound equipment more responsive and lighter weight. Aerospace engineers can reduce tool weights by 50% or more by substituting carbon fibers. Medical imaging equipment benefits from carbon fiber's sufficient strength and stiffness, maintaining critical dimensions under load without breaking down over time, even after high doses of X-ray and gamma radiation. The rigidity of carbon fiber, coupled with a weight of less than half that of aluminum, allows engineers to create innovations that will forge the next generation in consumer products and manufacturing.