Why You Should Opt for Custom Carbon Fiber Fabrication

If you search the internet long enough, you can find instructions on how to do just about anything yourself. In some cases, a handy person saves both time and money this way. However, sometimes it pays to let a professional handle the job. This is the case with custom carbon fiber fabrication. When you hire a professional for your custom carbon fiber fabrication job, you receive a lot of benefits that just don’t exist with DIY methods.

If you search the internet long enough, you can find instructions on how to do just about anything yourself. In some cases, a handy person saves both time and money this way. However, sometimes it pays to let a professional handle the job. This is the case with custom carbon fiber fabrication. When you hire a professional for your custom carbon fiber fabrication job, you receive a lot of benefits that just don’t exist with DIY methods.

Experience

Carbon fiber composites can be tricky to work with. Using an experienced carbon fiber fabricator to handle your job ensures parts meet the job specifications and significantly reduces the likelihood of part failure. Additionally, an experienced professional custom carbon fiber fabricator has access to the latest technology in the industry. Some of this technology is quite expensive to acquire, so only a professional fabricator would have access to it.

Availability of Components

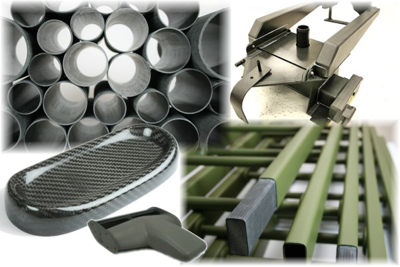

Your job might be custom, but that doesn’t mean there aren’t stock parts that can be used in the design. When you opt for custom carbon fiber fabrication, the fabricator likely already has some components in stock to use as part of the assembly, thereby saving both time and money. By combining “off-the-shelf” carbon fiber composite panels, tubes, beams, or trusses, a professional carbon fiber fabricator can build your product with a combination of custom and ready-made components.

Engineering, Design, and Analysis

Using a professional that specializes in carbon fiber composites means there are engineers on staff who are qualified to help you to analyze your design or even help you to create a design to meet your specific requirements. Your product is less likely to have structural or other issues when engineering analysis is performed before carbon fiber fabrication begins.

State-of-the-Art Equipment

When you opt for custom carbon fiber fabrication, the fabricator has access to top-of-the-line CNC machines and mills that are not available to the average DIY-er. Using such equipment ensures a significantly higher rate of precision and a better overall final product. Using your computer-aided design (CAD) file, a professional carbon fiber fabricator can CNC-cut your product to extremely precise specifications and return it ready to be installed.

Quality Standards

Your quality standards can be met when using a custom carbon fiber fabricator to build your assembly. A top-notch carbon fiber fabricator will be ISO 9001 certified, ensuring strict quality standards are upheld by following stringent process controls. Furthermore, the quality of your custom-fabricated carbon fiber product can be verified for accuracy of measurements and tolerance specifications. Every measurement can be verified during production, ensuring your expectations are met when the product is completed. Furthermore, dimensional certifications can be provided if they are needed.

Other Custom Carbon Fiber Fabrication Benefits

By opting for custom carbon fiber fabrication, you have a wide array of custom choices and selections available to you, such as:

- CNC-cut parts

- Sheet sizes

- Thicknesses

- Laminate layup schedules

- Cores

- Fabrics (Kevlar, fiberglass, and so on)

- Beams

- Braided carbon fiber tubes

- Truss structures

By opting for custom carbon fiber fabrication created by a professional fabricator, you will end up with a beautiful high-quality product with a high stiffness to weight.

For more information on DragonPlate’s process, visit our custom carbon fiber solutions page here.