Applications

DragonPlate™ carbon fiber composites have impressive specifications that make our materials attractive to customers across diverse markets. The physical properties of carbon fiber composites offer unique attributes that fulfill high-performance requirements for many industries. This includes properties like high stiffness, high tensile strength, high-temperature tolerance, chemical resistance, and fatigue resistance.

Keep reading to learn some practical carbon fiber applications.

Industrial Automation and Robotics

Industrial automation and robotics are beginning to realize the benefits of incorporating carbon fiber composite raw materials. For many applications, the ability to reduce weight and increase structural stiffness reflects directly in faster response time and reduces motor and actuator loads. This, in turn, results in improved productivity and longer maintenance cycles.

In industrial automation, machines often run as fast as possible 24/7. Reducing inertial loads by replacing heavy metal components with optimized composite material structures can reduce part cycle time and production costs, dramatically increasing profitability. In such applications, the return on investment in increased material costs associated with carbon fiber is often realized quickly.

DragonPlate large diameter tubes, gussets, and carbon fiber sheets can easily be assembled into frameworks for various robotic applications. DragonPlate can also customize the carbon fiber layup or dimensions to meet the customer's designed mechanical properties for uses where loads and deflections are of significant concern.

One example of DragonPlate carbon fiber materials is from the world of commercial robots. International Climbing Machines built a revolutionary wall-climbing robot, the chassis almost entirely made from DragonPlate carbon fiber. This robot is used in the nuclear industry, airplane inspection, and many other applications where the environment is either extremely harsh to humans or the ability to climb sideways and upside down would result in drastically reduced labor time (as in the case of inspecting an airplane fuselage or wing). By replacing the original metal structure with a high strength-to-weight ratio DragonPlate material, ICM was able to increase the robot's performance and payload-carrying ability significantly.

Learn More About Carbon Fiber Industrial Automation and Robotics:

Industrial Automation and Robotics

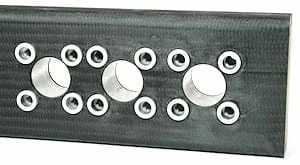

Carbon Fiber Idler Rollers

Dragonplate manufactures various carbon fiber tubes useful for idler rollers, ranging from standard modulus tubes with stiffness comparable to aluminum to ultra-high modulus tubes more rigid than steel.

Learn more about Carbon Fiber Idler Rollers:

Carbon Fiber Idler Rollers

UAVs and Drones

Dragonplate has the building materials you will need to create virtually any drone, from the hobbyist to the professional. Our off-the-shelf line of carbon fiber sheets, braided and roll-wrapped tubes, angles, and a wide array of pultruded materials provide all the basics. Our patented connector system for pultruded tubes and our modular connectors for braided and roll-wrapped tubes provide an ideal method for making frames, especially for multi-rotor helicopters. For assembly, an array of structural epoxies and fasteners are also available.

Learn More About Using DragonPlate Carbon Fiber Composites to Build UAVs and Drones:

UAVs and Drones

Carbon Fiber for Marine and Aircraft Interiors

Dragonplate offers various off-the-shelf products and custom fabrication services to support the luxury yacht and aircraft interiors industry. Whether for an individual, corporation, or government client, the properties of carbon fiber composites can benefit your designs in two ways: weight reduction and high-tech distinctiveness.

This is particularly true when designing the interior for aircraft since every pound saved means improved efficiency and additional payload elsewhere in the vehicle. Weight and balance are also significant for large yachts, where weight saved above the water line can help. Carbon fiber also offers corrosion resistance, making it an ideal material for the marine and aircraft industry.

Learn More About Carbon Fiber Marine and Aircraft Interiors:

Marine and Aircraft Interiors

Aerospace Tooling and Manufacturing Fixtures

The challenge with manufacturing tooling, particularly aircraft production tools, is that they can be very large and thus heavy and difficult to move. Dragonplate regularly helps customers reduce tool weights by 50% or more. Using FEA calculations, weight reductions up to 75% are sometimes possible compared to older aluminum and steel tools and fixtures.

Learn More About Carbon Fiber Aerospace Tooling and Manufacturing Fixtures:

Aerospace Tooling and Manufacturing Fixtures

Carbon Fiber Electronics Enclosures

There are several benefits of lightweight carbon fiber electronic enclosures. Our customers primarily look to carbon fiber's advanced mechanical properties for these applications to reduce weight.

In addition to reduced weight and increased natural frequency, carbon fiber electronic enclosures maintain dimensional tolerances over a much wider temperature range than plastic or metal enclosures. Carbon fiber's thermal expansion coefficient (CTE) is approximately the same as Invar, thus significantly reducing thermal issues for sensitive electronics, lasers, mirrors, and sensors.

Learn More About Carbon Fiber Electronics Enclosures:

Carbon Fiber Electronics Enclosures

Composite Radar Structures

Dragonplate has been building radar structures for military applications for over a decade. The advantage of carbon fiber, fiberglass, and Kevlar in such a unit is apparent when one considers the challenges of moving equipment to remote locations.

Lightweight carbon fiber composites can mean the difference between something that is carried and a system that must be moved by vehicle. And even vehicle and aircraft-mounted radar systems benefit significantly from reduced weight.

Learn More About Carbon Fiber Composite Radar Structures:

Carbon Fiber Composite Radar Structures

Medical Imaging, X-Ray, and Gamma-Ray Applications

Carbon fiber has rapidly become a primary material in medical imaging, X-ray, and gamma-ray applications. In particular, carbon fiber provides a radiolucent material with sufficient tensile strength and stiffness to maintain critical dimensions under load. It will not break down, even after high X-ray and gamma-ray radiation doses.

Learn More About Carbon Fiber Medical Imaging, X-Ray, and Gamma-Ray Applications:

Medical Imaging, X-Ray, and Gamma-Ray Applications

Metrology and Scientific Equipment

Carbon fiber is rapidly becoming one of the choice materials in the field of metrology due to its high stability and low thermal expansion. In applications where thermal changes will move comparable metal measurement and alignment tools out of tolerance due to expansion or contraction of the material, carbon fiber will remain virtually unchanged over a wide temperature range.

Learn More About Carbon Fiber Metrology and Scientific Equipment:

Metrology and Scientific Equipment

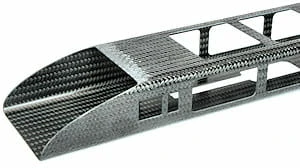

Tactical Military and SWAT Gear

Dragonplate regularly collaborates with military and SWAT police to develop new and innovative solutions to tactical problems. A key example includes our patented carbon fiber ladder system, which began with members of the Special Forces community requesting a piece of equipment that was lighter, more portable, and stronger than the current telescoping and fold-out ladders they had available.

The collaboration between Dragonplate and soldiers included evaluation and feedback on early models. This allowed our team to create a product designed to meet the mission requirements of the Marines and Army and Navy Special Forces with whom we worked.

Learn More About Carbon Fiber Tactical Military and SWAT Gear:

Tactical Military and SWAT Gear

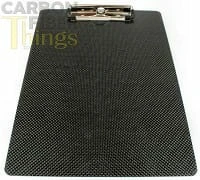

Carbon Fiber Luxury Items and Corporate Gifts

Dragonplate offers various composite materials for inclusion in corporate and executive gifts, custom awards, trophies, medals, and other similar applications. Carbon fiber provides your project with a high-tech, classy look and feel. Dragonplate works closely with companies in the custom awards and corporate gifts industry to help make these products stand out.

Learn More About Carbon Fiber Luxury Items and Corporate Gifts:

Carbon Fiber Luxury Items and Corporate Gifts

Carbon Fiber for Trade Shows and Interior Design

Carbon fiber is increasingly used in the construction of trade show booths and within the more general scope of interior design for weight savings and the high-tech associated with carbon composites. DragonPlate offers a wide range of off-the-shelf products to create high-end booths or interiors.

Learn More About Carbon Fiber for Trade Shows and Interior Design:

Carbon Fiber for Trade Shows and Interior Design

Musical Instruments

Carbon fiber strips serve many applications in musical instruments, where its material properties of low mass and high stiffness make it an ideal choice. Carbon fiber strips or our patent-pending D-Tube may be used in various configurations for neck reinforcement in wood necks. Short strips can be used to strengthen the headstock joint. Carbon fiber strips may be used in guitar bracing, combined with balsa or spruce as a stiffening laminate. Strips may also be used in lattice support bracing of the top plate to allow greater thinning for increased response.

Some makers have found other creative applications in using carbon fiber strips as longitudinal internal supports for reducing stress on top-sounding plates. Due to its high strength in compression/tension and low mass and its excellent bonding with epoxy and cyanoacrylate adhesives, carbon fiber is the doorway to new-generation instrument making.

One of the most common uses of carbon fiber in the making and repairing stringed instruments is neck reinforcement. This image exemplifies how carbon fiber can stabilize the neck and reduce twisting. This neck cross-section shows one possible way to install carbon fiber. The cross-sectional dimensions of your neck determine the orientation of carbon fiber strips.

Carbon Fiber Furniture

Carbon fiber is increasingly being used in the construction of furniture. Furniture makers use carbon fiber because of its light weight, durability, and appearance. Carbon fiber can give a piece of furniture a "high-tech" or "high-end" look while reducing weight.

Learn More About Carbon Fiber Furniture:

Carbon Fiber Furniture

Advancing Sporting Goods

Carbon fiber has revolutionized the sporting goods industry, from fishing rods to golf clubs, elevating performance and pushing the boundaries of athletics. In various sporting disciplines, this versatile material has found multifaceted applications. In cycling, it creates ultralight yet rigid frames for bicycles. Tennis Rackets infused with carbon fiber exhibit offer increased power and control. Valued as a lightweight material, performance carbon fiber is used to manufacture lightweight paddles, oars, and surfboards in water sports, enhancing maneuverability and reducing fatigue. Golf has embraced the benefits of carbon fiber. Modern golf clubs integrate carbon fiber into club heads and shafts to precisely control weight distribution and balance.