Wed, Jun 10, 2020 Carbon Fiber vs Aluminum

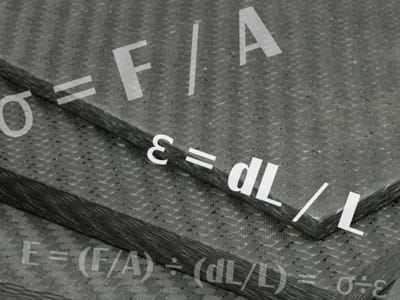

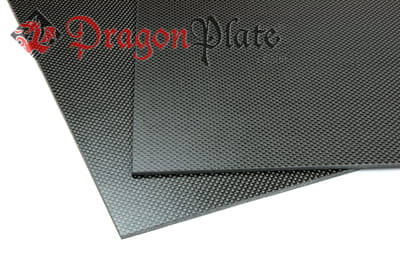

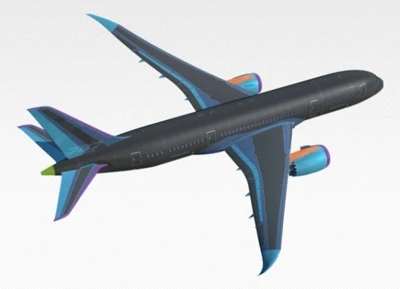

Carbon fiber is replacing aluminum in an increasing variety of applications and has been doing so for the last few decades. This article provides a comparison of the properties of carbon fiber versus aluminum, along with some pros and cons of each material.