Blog

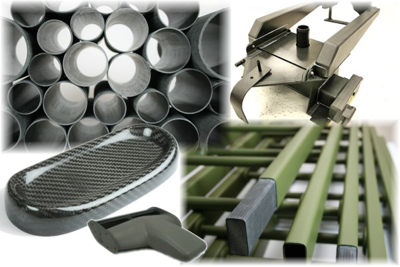

Tubular structures are useful for a wide array of applications. Therefore, it should come as no surprise that the unique properties of carbon fiber tubes place them in high demand in many industries. More and more often these days, carbon fiber tubes replace steel, titanium, or aluminum tubes in applications where weight is an important factor.

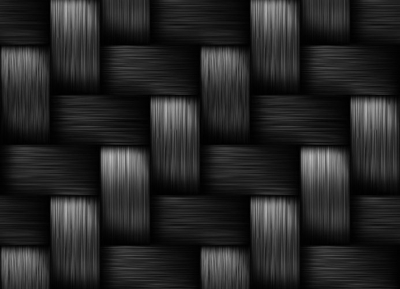

After carbon fibers have been manufactured and sized, they are often woven into fabrics. There are many different types of fabrics to choose from and have many different uses.

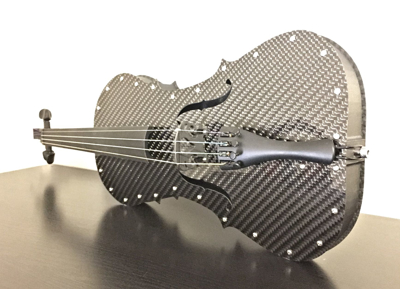

While the basis of carbon fiber—fibers made of carbon—sound simple enough, there are myriad ways to combine these relatively simple fibers, often with other products, to create the stronger, stiffer, and lighter materials highly favored by design engineers for modern high-tech projects.

Although carbon fiber has been around for more than 150 years, it has only been through manufacturing process improvements in the last half century or so that its excellent strength-to-weight and stiffness-to-weight ratios have been achieved. These modern advances, coupled with decreases in manufacturing costs over the last couple of decades, are what have made carbon fiber become such a popular material for design engineers to use in some of today's greatest technological advances.

- 2025

- 2023

- 2022

- 2021

- 2020

- 2019

- 2018