Cookies help us deliver our services. By using our services, you agree to our use of cookies.

Close

-

Carbon Fiber Veneer Sheets

- Back

-

Plain Weave Veneer Show All Products- Back

-

Twill Weave Veneer Show All Products- Back

-

Twill Narrow Weave Veneer Show All Products- Back

-

2-Layer Veneer .025" Show All Products- Back

-

Two Sided Satin Twill Veneer Sheets Show All Products- Back

-

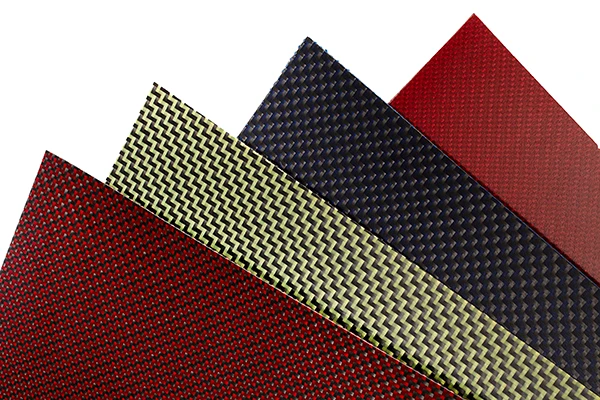

Twill Weave Red Kevlar Veneer Show All Products- Back

-

Twill Weave Carbon/Kevlar (Yellow) Veneer Show All Products- Back

-

Twill Weave Carbon/Kevlar (Red) Veneer Show All Products- Back

-

Twill Weave Carbon/Kevlar (Blue) Veneer Show All Products- Back

-

Harness-Satin 4 Weave Veneer Show All Products- Back

-

Carbon Fiber Sheets and Plates

- Back

-

EconomyPlate™ Carbon Fiber Sheets Show All Products- Back

-

Quasi-isotropic Carbon Fiber Sheets Show All Products- Back

-

Carbon Fiber Twill/Uni Prepreg Sheets Show All Products- Back

-

Carbon Fiber Uni Prepreg Sheets Show All Products- Back

-

High Modulus Carbon Fiber Sheets Show All Products- Back

-

High Temp. Carbon Fiber Prepreg Sheets Show All Products- Back

-

Carbon Fiber Twill Prepreg Sheets Show All Products- Back

-

Two Sided CF Sheets Show All Products- Back

-

ArtisanPlate™ Carbon Fiber Sheets Show All Products- Back

-

Carbon/Kevlar Hybrid Sheets Show All Products- Back

-

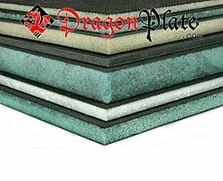

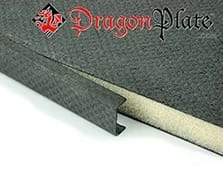

Carbon Fiber Sandwich Sheets with Core

- Back

-

Carbon Fiber Birch Core Show All Products- Back

-

Carbon Fiber Prepreg Birch Core Show All Products- Back

-

Carbon Fiber Balsa Core Show All Products- Back

-

Carbon Fiber Honeycomb Core Show All Products- Back

-

Carbon Fiber Foam Core Show All Products- Back

-

Carbon Fiber Dyneema® Core Sheets Show All Products- Back

-

Carbon Fiber Flax Linen Core Sheets Show All Products- Back

-

Carbon Fiber Core Trim Show All Products- Back

-

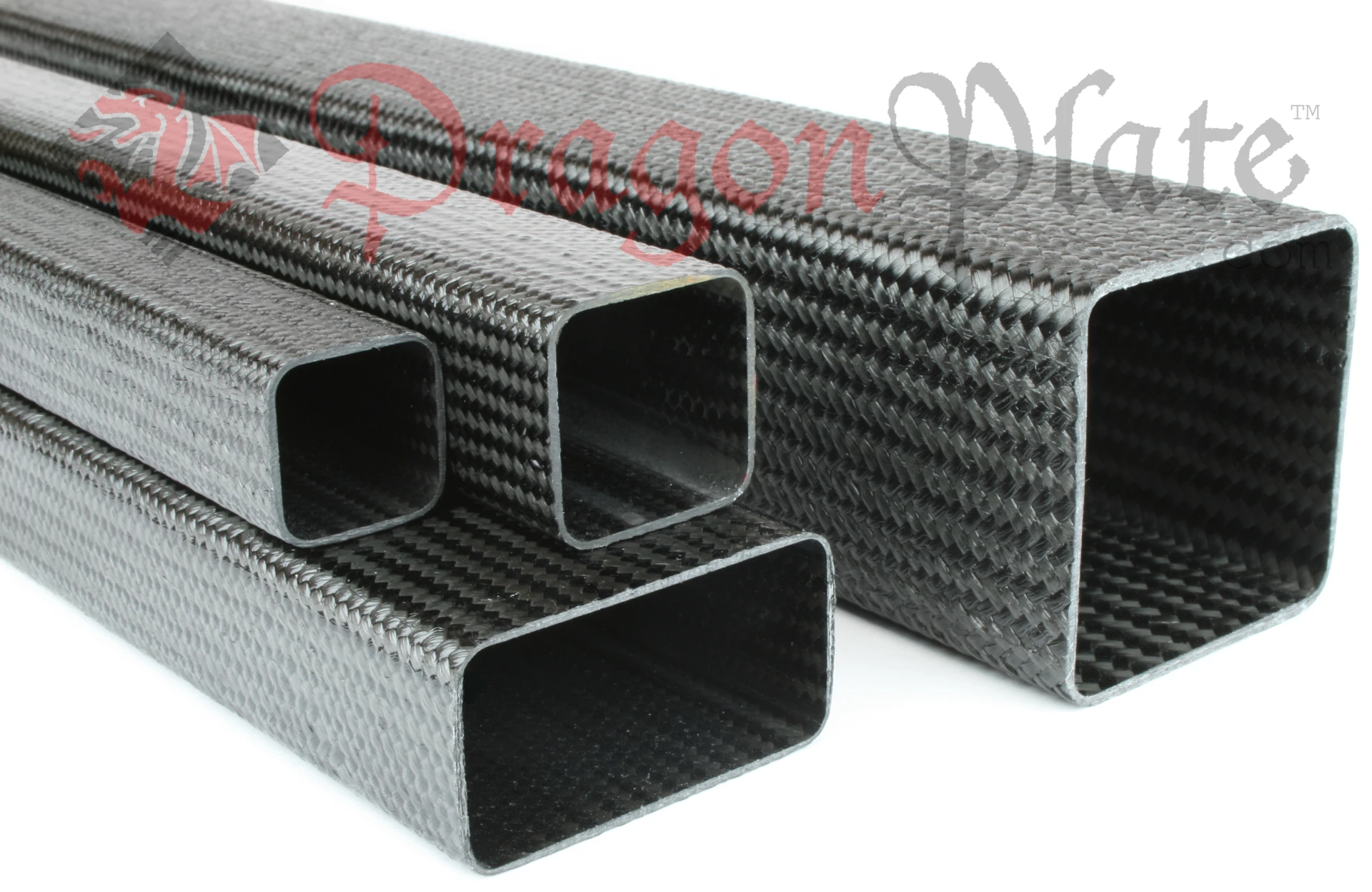

Carbon Fiber Tubing

- Back

-

Roll Wrapped Carbon Fiber Round Tubes Show All Products- Back

-

Roll Wrapped Twill Finish Square & Rectangle Tubes Show All Products- Back

-

Roll Wrapped Tapered Carbon Fiber Tube Show All Products- Back

-

Braided Carbon Fiber and Kevlar Round Tubes Show All Products- Back

-

Braided Carbon Fiber Square/Rectangular Tubes Show All Products- Back

-

Braided Carbon Fiber Hexagonal Tubes Show All Products- Back

-

Streamlined Symmetrical Airfoil Carbon Fiber Tubing Show All Products- Back

-

Large Carbon Fiber Tubes Show All Products- Back

-

Carbon Fiber Tube Splices Show All Products- Back

-

Pultruded Carbon Fiber Tube Show All Products- Back

-

Carbon Fiber Camera Rails Show All Products- Back

- Carbon Fiber Telescoping Tubes

- Tube Connector Systems

- Structural Carbon Fiber Components

- Pultruded Carbon Fiber Components

- High Temperature Carbon Fiber

-

Flame Retardant Carbon Fiber

- Back

-

Flame Retardant Plain Veneer Show All Products- Back

-

Flame Retardant Veneer 2-Layer .025" Show All Products- Back

-

Flame Retardant Twill Veneer Show All Products- Back

-

Flame Retardant EconomyPlate Sheets Show All Products- Back

-

Flame Retardant Braided Carbon Fiber Round Tubes Show All Products- Back

-

Flame Retardant Carbon Fiber Angle Show All Products- Back

-

Flame Retardant Carbon Fiber C-Channel Show All Products- Back

-

Flame Retardant Carbon Fiber Hat Stiffeners Show All Products- Back

-

Flame Retardant Carbon Fiber I-Beams Show All Products- Back

-

Flame Retardant Braided Carbon Fiber Square/Rectangular Tubes Show All Products- Back

-

Flame Retardant Carbon Fiber Twill Prepreg Sheets Show All Products- Back

-

Flame Retardant Twill Color Veneer Show All Products- Back

-

Flame Retardant Narrow Weave Twill Veneer Show All Products- Back

-

Kevlar Composite Products

- Back

-

Kevlar Tubes Show All Products- Back

-

Kevlar Sheets Show All Products- Back

- Adhesives & Applicators

-

Additional Items

- Back

-

Bonded Fasteners Show All Products- Back

-

Polishes Show All Products- Back

- Carbon Fiber Quadcopter Kits

- About

- Shop Products

- What Is Carbon Fiber?

- Applications

- Custom

- Contact

- Blog

- TECHNICAL SPECS

- Home /

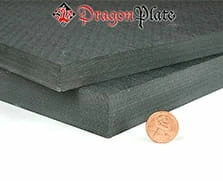

- Carbon Fiber Sandwich Sheets with Core /

- Carbon Fiber Flax Linen Core Sheets /

- Carbon Fiber Prepreg Ekoa® Flax Linen Core Sheet - 1/16" x 12" x 12"

DragonPlate® Engineered Carbon Fiber Composites

Information

Customer Service

My Account

Contact Info

-

Call Us

315-252-2559 -

Working Hours

Mon-Fri 8:30am - 5:00pm ET